Production of cords, electrical harnesses and harnesses

On all dimensions and for all sectors of activity, MtC supports you in the production of cords, electrical harnesses and harnesses.

On small, medium and large series.

We carry out for you:

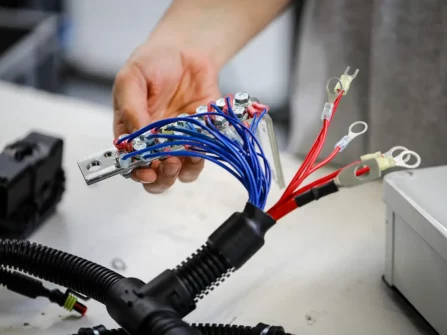

- Simple wiring

- Multi-branched harnesses

- Integration and assembly of electrical components in electrical systems

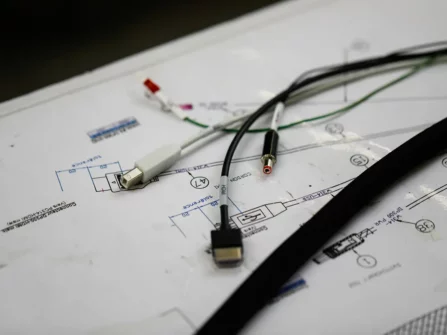

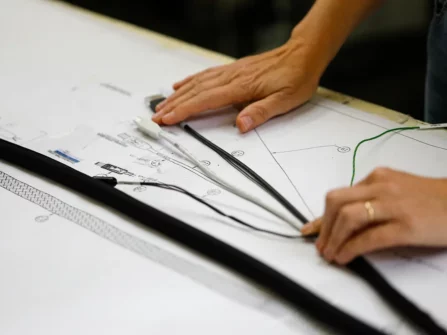

After the industrialization stage where prototyping is carried out to be sure to meet your expectations and possibly check functionality if necessary, we adopt different manufacturing processes on any different manufacturing supply:

- Cut to length

- Marking

- Compaction analysis

- Stripping

- Crimping

- Shunting, splicing

- Shaping

- Simple or thermoformed sheathing

- Partial wrapping

- Tin solder (with or without lead)

- Integration and assembly of parts

- Mechanical engraving

We are able to work with large connections as well (eg. power wiring for batteries (AWG4/0 wires) as well as micro connectors (AWG28 wires).

Finally, MtC carries out the control of each product manufactured through:

- Visual conformity check (check deformation of the terminal)

- Checking resistance to tearing (destructive test)

- Dimensional control (height and width measurements of the crimp)

- Control of compaction (microscopic analysis of crimping in section)

- Automatic control on crimping press (in production)

- Control by calibration (validate machine/tool capability)